An Ingress Protection Rating, or IP Rating, grades the resistance of an enclosure against the intrusion of dust and water and the ease in which individuals can access potential hazardous parts within the enclosure. Used widely in the industry, it provides a standardized method to evaluate/test a device’s resistance to environmental conditions and the suitable environment for the device, or lighting fixture.

The numerical rating consists of two numbers, the first digit [zero (0) to six (6)] refers to the protection against solid objects and the second numeral rates the protection against water [zero (0) to nine (9)]. In both cases, zero (0) represents no protection.

In some instances, the numeral position may contain the letter X, indicating no data/testing to specify ingress protection. IP Ratings may also contain a third supplemental digit, which indicates additional protection or testing conditions. This is more commonly seen in industrial equipment and enclosures, not typically in luminaire IP Ratings.

When evaluating IP Ratings for lighting fixtures, the ratings help to evaluate the appropriate environmental conditions that the luminaire can withstand since environments can vary greatly. Think of interior spaces such as bathrooms, covered porches, or fully exposed exteriors , all these spaces have different levels of exposure to contaminants and water.

The most common IP Ratings for exterior luminaires include IP65, which indicates a fully dust-tight lighting fixture that is also protected against water jets, and IP68, also indicating a fully dust-tight product but can also be fully submerged in water, such as in a pool or pond.

IP Ratings give the user and specifier the confidence that the product will not prematurely fail because of intrusion from dust or water and help determine if a fixture is safe for use in that environment.

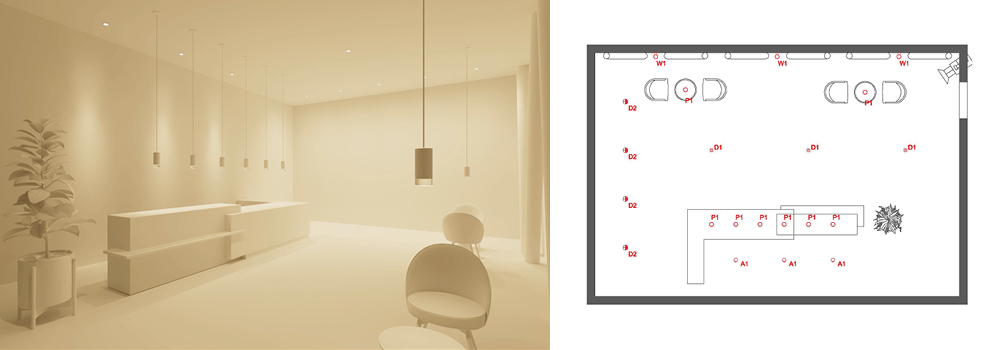

DMF Lighting offers several fixtures with IP Ratings that can be used in exterior applications with frequent exposure to water and harsh elements. Those fixtures include:

- M Series Commercial Downlights – The M Series Commercial Vandal Trim features a gasketed seal and IK10 (impact-rated) lens that offers IP66 level protection when installed in an appropriate ceiling. Available in both round and square standard trims, look for the “VP” option at the end of the trim product code.

VP = Vandal Proof/IP66

- M Series Cylinders & X Series Cylinders – These cylinders are highly configurable with up to 14+ million possible combinations. Each have options for IP65-Rated Pendant, Wall Mount, and Surface Mounted versions. When building your configuration, look for the water droplet next to the options that will fulfill an IP65 Rated option:

- H Series Wall Mount Cylinders – These cylinders are easy to order and do not require any special configuration to meet the IP65 rating.

Numeral Definitions

For a deeper dive into IP Ratings, including the rigorous testing procedures and the differences between IP Ratings versus UL Listings, check out our Technical Bulletin.